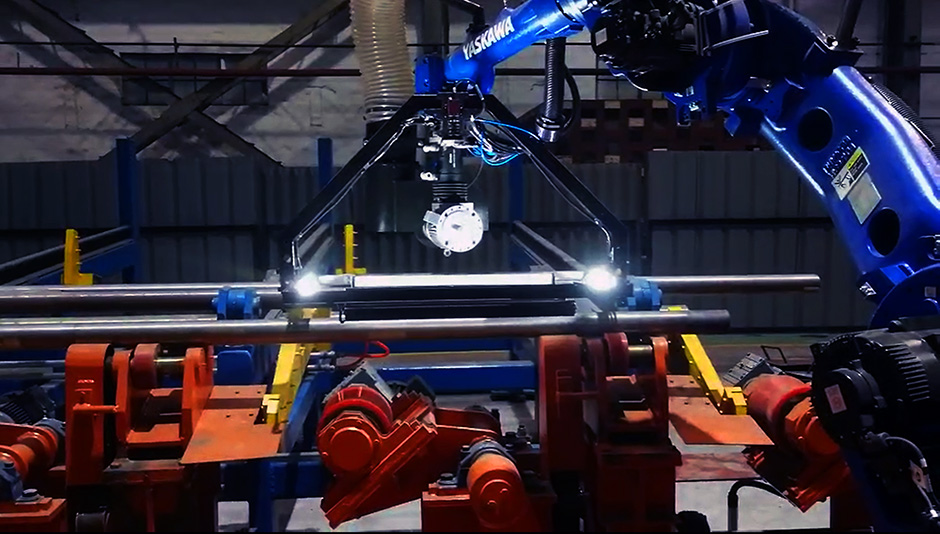

Project requirements:

1. After bars are formed, there may be cracks on the surface. This project requires the robot to detect the position and depth of defects with non-destructive testing, and then transmit the information to the grinding robot system to perform intelligent grinding.

2. The precision of the grinding depth is controlled within 0.1mm. After grinding, the surface is smooth and the roughness is Ra1.6.

3. Adapt to various types of bars.

How iGrinder® solved key problems in this application:

Key Problem # 1: Trajectory error and abrasive wear compensation

Through force feedback, iGrinder® always maintains the consistent contact between the grinding tool and the workpiece, eliminating the effects of trajectory errors and abrasive wear.

Key Problem #2: Process consistency

The classic grinding theory holds that the grinding amount is constant when the three parameters of grinding pressure, grinding time and abrasive grinding capacity are fixed. iGrinder® always maintains a constant grinding pressure, supplemented by excellent abrasives, ensuring the consistency of the process.

Key Problem #3---the biggest challenge: Grinding amount control

The system adopts SRI intelligent polishing software platform SriOperator3.0. The software focuses on the field of robot force-controlled grinding, and can intelligently analyze force sensor data, displacement sensor data, robot actual coordinates, visual system data, etc., and formulate personalized grinding process plans.

In order to control the amount of grinding, SRiOperator3.0 first obtains production line data from the vision system. During the grinding process, the software collect data of the robot coordinates and force and displacement from iGrinder in real time. Based on the spatial geometric algebra analysis of robot coordinates and displacement sensor data, the software calculates the actual grinding amount, then controls the parameters, i.e. grinding pressure, grinding time, grinding speed of iGrinder to finally achieve control of the grinding amount

Contact us to know more about SRI iGrinder!

*iGrinder® is the intelligent force-controlled floating grinding head with Sunrise Instruments (www.srisensor.com, SRI for short) patented technology. The front end can be equipped with a variety of tools, such as air mill electromechanical spindles, angle grinders, straight grinders, belt machines, wire drawing machines, rotary files, etc., suitable for different application scenarios.

The system was jointly developed by Sunrise Instrument (SRI) and Jiangsu Jinheng. SRI provided the iGrinder® intelligent power control polishing solution, and Jinheng provided the vision system and project integration. The end customers of bar repairing can contact Jiangsu Jinheng to discuss cooperation matters.