The collision force sensors shipped this time include 128 standard version collision force wall sensors and 32 lightweight version collision force wall sensors, which will play important roles in the rigid collision wall and MPDB experiments, respectively. These sensors can accurately monitor the parameters during the collision process in real time, providing a solid support for the improvement of car safety performance.

As early as 10 years ago, there were three sets of high-resolution collision walls designed and produced by the US Department of Transportation’s Collision Laboratory providing collision testing services. I have been serving the US Department of Transportation’s Collision Laboratory for over 10 years now. Sunrise Instruments will help the automotive industry improve safety performance and bring consumers a safer and more comfortable driving experience. Contribute to the protection of life safety.

The collision force wall is a key equipment in the field of automotive collision compatibility, and the collision force wall sensor can measure the collision force in the XYZ direction.

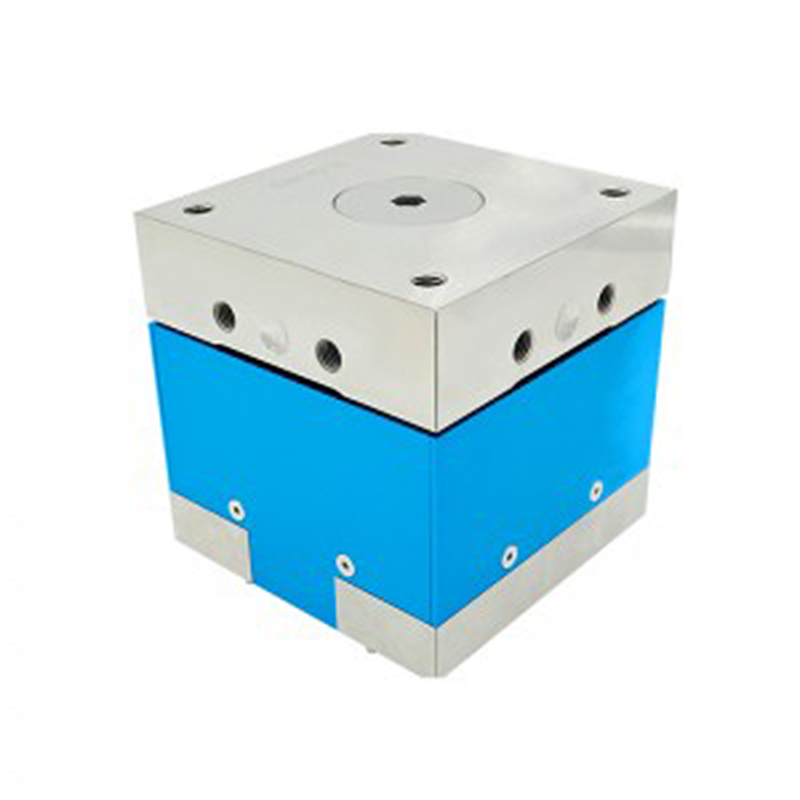

The collision force wall sensors of Sunrise Instruments are divided into two categories: standard version and lightweight version.

The range of the sensor covers the range of 50KN to 400KN, with a length and width of 125mm * 125mm, making it convenient to form a rigid collision force wall. The standard version weighs 9.2kg and is used for rigid frontal collision testing;

The lightweight version weighs only 3.9kg and is particularly suitable for MPDB testing.

The Yuli Instrument collision force wall sensor supports both analog and digital outputs, and the digital output sensor integrates an iDAS data acquisition system internally. IDAS amplifies, filters, samples, and converts sensor data into digital communication for easy transmission to the system bus.

The force sensor is installed from the front to the base, and a controller communication bus is embedded inside the base, so that all force wall sensors are controlled and sampled by the controller.

The bus structure is convenient for disassembly and management.

Excellent performance: Nonlinear<=0.5% F.S; Hysteresis<=0.5% F.S; Crosstalk<=2% F S; Resonance frequency ≈ 3200Hz;

Upgradeable: Upgradeable to the same version as NHTSA, obtaining an average collision force height of AHOF.

Multi application: Standard type, suitable for frontal and rigid collision testing; Lightweight, suitable for MPDB testing when two vehicles collide.

Reliable and easy to use: Front mounted, easy to maintain and disassemble, can integrate data acquisition system internally, digital output, high reliability.

Calibration service: We will provide customers with comprehensive and easily accessible calibration services.

Force measurement wall configuration:

Each sensor has a length and width of 125mm * 125mm, making it convenient to form a rigid collision force wall of 1m * 2m or other sizes. The sensor is installed from the front to the rigid wall, making it easy to disassemble and assemble.

MPDB configuration:

SRI offers a lightweight version of the collision force wall sensor, weighing only 3.9kg.

The lightweight version provides a better solution for the overall size, weight, and CG requirements of the trolley, making it particularly suitable for MPDB testing.

Column collision test configuration:

The side and front of the sensor are equipped with screw holes for installing cylinders, which are mounted on the sensor from the front.

The sensors used in the column impact test are the same as those used in the force measurement wall, effectively reducing cost consumption.